Digital Printing Advantages: Streamlining Modern Production Processes

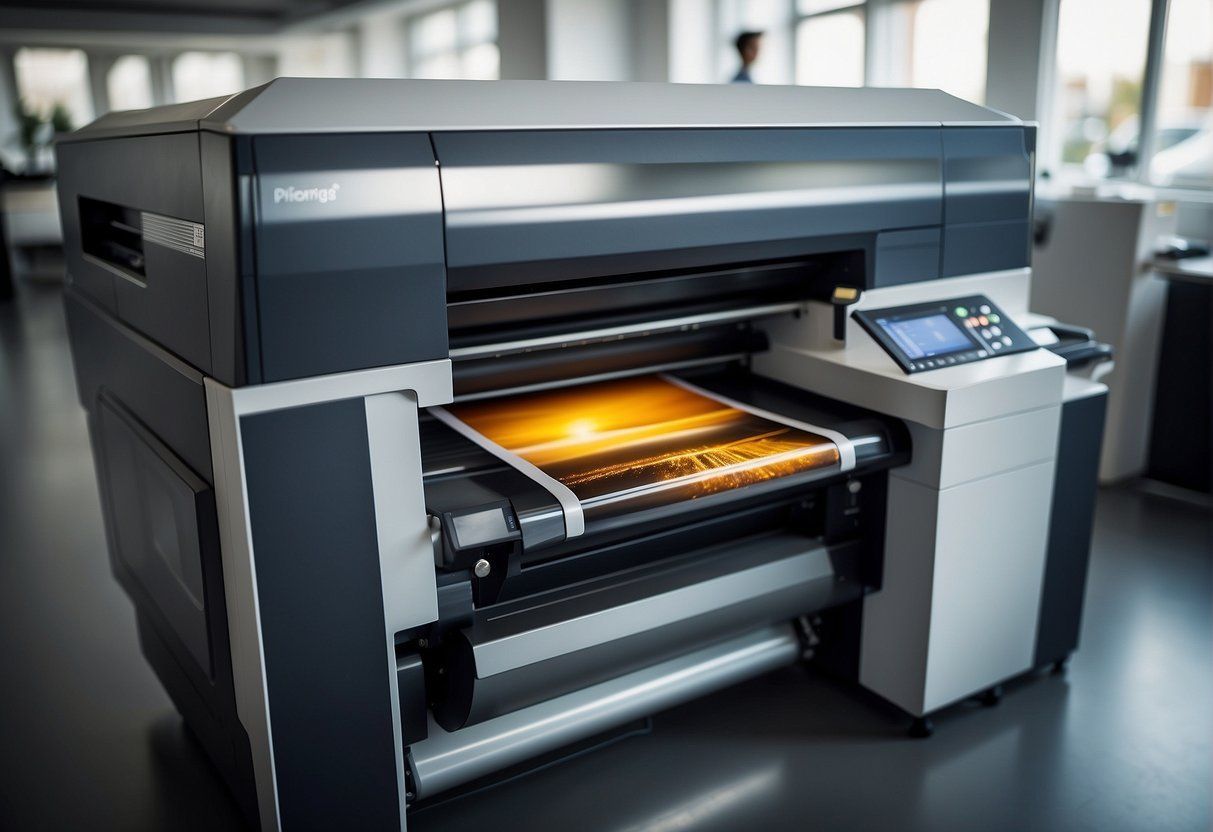

Digital printing refers to a modern method of printing from a digital-based image directly to a variety of media. Historically, printing to a large extent involved long and complex processes, such as setting up printing plates; however, digital printing has simplified these steps. One of the major advantages of digital printing is its efficiency. Unlike traditional printing methods that require plate setup and a lengthy preparation process, digital printing offers a fast turnaround due to the minimal setup time involved. This makes it an ideal solution for on-demand printing and for projects that require a quick completion time.

Another significant advantage of digital printing is its ability to produce high-quality prints with excellent resolution and clarity. The technology supports a wide range of colors and gradients, enabling vibrant and accurate color reproduction. This quality aspect makes digital printing suitable for detailed graphics and images that demand precision and a high level of visual fidelity. Moreover, digital printing is versatile in terms of the substrates it can print on, allowing a variety of applications from paper and plastic to fabric and ceramics.

The cost-effectiveness of digital printing is particularly evident when dealing with small to medium print runs. Traditional offset printing involves higher initial costs due to the preparation of plates, making it less economical for small quantities. In contrast, digital printing does not require such upfront costs, which translates to a lower cost per unit for short runs. Additionally, customizing individual prints within the same job is straightforward with digital printing, which enhances its appeal for personalized products and services that cater to individual preferences or targeted marketing campaigns.

Comparing Digital and Traditional Printing

This section directly contrasts digital printing with traditional offset printing, focusing specifically on cost and setup, as well as the capacity for customization.

Digital vs. Offset Printing

Traditional printing, often referred to as offset printing, requires the creation of printing plates which are used to transfer ink onto the paper. It’s a process well-suited for large print runs. Digital printing, on the other hand, does not use printing plates, and works similarly to how a desktop printer operates but on a larger scale. It’s ideal for shorter print runs and quick turnarounds.

Cost and Setup Considerations

- Setup Costs

:

- Offset Printing : Higher initial setup costs due to the need for creating printing plates.

- Digital Printing : Lower setup costs as it doesn’t require printing plates or additional setup time.

- Cost-Effectiveness

:

- Offset Printing : More cost-effective for large volume jobs due to economies of scale.

- Digital Printing : More economical for small to medium jobs with fewer upfront costs.

Flexibility and Customization

Digital printing offers superior flexibility and customization compared to traditional offset printing. It allows for:

- Variable Data Printing : The ability to change elements such as text and images from one print to the next without slowing down the process.

- Print-on-Demand : The option to print exactly the quantity needed with minimal waste, ideal for customized orders and small print jobs.

- Quick Revisions : Easy editing and updating of content without the need for new plates, providing quicker response to market demands.

Technological Advancements in Digital Printing

The digital printing landscape has undergone a transformation, driven by innovation in printer technology and a shift towards sustainability. The industry is redefining precision and consistency while adopting eco-friendly practices.

Inkjet and Laser Printers

Inkjet printers have significantly evolved due to advanced nozzle technology that allows for greater control of ink distribution. The integration of Artificial Intelligence (AI) further enhances printer performance, with algorithms optimizing ink usage and reducing waste. The table below illustrates key advancements in inkjet and laser printers:

| Feature | Inkjet Printers | Laser Printers |

|---|---|---|

| Printing Method | Propels droplets of ink onto the substrate | Uses toner and heat to fuse images onto paper |

| Color Quality | High-quality color output with a wide color gamut | Strong at producing sharp text and consistent color reproduction |

| Speed | Improvements in print head technology have increased speed | Generally faster than inkjet for high volume printing |

| Material Variety | Can print on a wide range of substrates | Best suited for standard printing papers |

Precision and Consistency

Digital printers have benefitted from enhancements in printing technology that ensure precise and consistent results. Laser printers stand out for their exceptional ability to produce accurate and uniformly high-quality text prints. Inkjet technology, on the other hand, provides consistent quality in color printing, with recent models exhibiting improved detail and color accuracy.

Eco-Friendly Practices

The printing industry is increasingly adopting eco-friendly practices. Newer digital printers utilize eco-friendly inks and toners that are less harmful to the environment. Energy-efficient models and responsible ink disposal methods are becoming standard. These developments reflect a commitment to sustainability:

- Reduced Waste: Digital printers produce less waste by avoiding the need for printing plates and allowing for on-demand printing.

- Energy Usage: Newer models are designed to consume less energy, contributing to a reduction in the industry’s carbon footprint.

- Materials: The use of sustainable materials in printer manufacturing and recycled materials for toner cartridges is on the rise.

These subsections encapsulate how the digital printing sector is embracing technological advancements for better performance and sustainability.

Advantages of Digital Printing for Business

Digital printing offers significant benefits for businesses looking to improve their marketing materials with personalization while maintaining cost-effectiveness and efficiency. Short-run and on-demand printing services further enhance its appeal as a modern printing solution tailored to the fast-paced market demands.

Marketing and Personalization

Businesses can harness digital printing to produce high-quality marketing materials that feature crisp detail and vibrant colors. With variable data printing , companies can include a personalized message on each item, making marketing efforts more impactful. Labels , brochures, and flyers can be tailored to address customers directly, increasing the relevance and effectiveness of the campaign as a potent marketing tool .

Cost-Effectiveness and Efficiency

Digital printing stands out for its cost-effective production of shorter runs, which is not as economical with traditional offset printing. By eliminating the need for printing plates, businesses benefit from lower setup costs and a quicker turnaround . This efficient process allows for frequent updates to marketing materials without incurring significant expenses, making it a smart choice for businesses watching their bottom line while striving for high-quality output.

Short-Run and On-Demand Printing

The ability to execute short-run production and print on demand is a cornerstone of digital printing. This approach aligns with just-in-time production strategies, reducing the waste associated with excess inventory. Companies can print exactly what they need, when they need it, offering a flexible service that mitigates storage issues and ensures sales materials are always up-to-date. This responsiveness to market changes is invaluable for businesses aiming to maintain an edge in their respective industries.

Quality and Versatility in Output

Digital printing stands out for its capability to produce high-quality, accurate prints on a wide array of substrates. This process ensures consistent quality, whether for small print runs or complex projects requiring intricate finishing options.

Substrate Compatibility

Digital printers excel in handling diverse materials ranging from paper stock and cardstock to canvas, fabric, and various synthetics. The advanced technology behind these printers allows for:

- Paper Stock and Photo Paper: Smooth and efficient printing on standard and specialized papers.

- Fabric and Canvas: Ability to print vibrant colors with high resolution, while maintaining the softness and texture of the fabric.

- Synthetics and Cardstock: Printing with precision on durable materials, suitable for a range of applications.

High-Quality Output

Digital printing employs liquid ink or toner to achieve:

- High-Resolution Images: Sharp details and crisp lines thanks to advanced printing technology.

- Color Accuracy: Utilizing CMYK color models to ensure accurate color reproduction.

- Precision and Durability: Outputs that are not only precise in design but also boast durability for extended use.

Finishing Options

After printing, digital printers provide myriad finishing possibilities to enhance the durability and appearance of the printed materials. Some common finishing techniques include:

- Lamination and Coating: To protect against moisture and wear, increasing the longevity of the print.

- Trimming and Binding: Precisely cut edges and various binding options for books, brochures, and other multi-page documents.

- Custom Cuts and Shapes: Tailor-made options for promotional materials, packaging, and stand-out business collateral.

Sustainability and Future Trends

Digital production print technology is reshaping the print industry’s approach to sustainability and efficiency. Manufacturers are focusing on advancements and innovations that reduce environmental impact while enhancing productivity.

Advancements Toward Sustainability

The shift toward eco-friendly digital printing solutions reflects a significant change in manufacturing processes. Digital printing minimizes waste through precise ink application and on-demand printing capabilities. Notably:

- UV Printing : Uses ultraviolet light to dry ink instantly, reducing energy consumption and eliminating the need for harmful solvents.

- Materials : Development of recyclable and biodegradable substrates significantly diminishes the environmental footprint.

Innovations in the Print Industry

Innovations in the print industry not only drive sustainability but also improve operational aspects. Key innovations include:

- Faster Turnaround Times : Digital printing accelerates production cycles, enabling rapid response to market demands and contributing to leaner inventory management.

| Innovation | Benefit |

|---|---|

| On-Demand Printing | Reduces excess stock and waste |

| Automated Color Calibration | Ensures consistency, reducing reprints and material usage |

- Brand Recognition : Customizable short-run prints allow for targeted marketing, enhancing brand recognition without the excess of traditional bulk printing.

Frequently Asked Questions

The section below addresses common inquiries regarding the advantages of digital printing compared to traditional methods, focusing on its benefits for short runs, on-demand printing, customization, quality, and environmental impact.

What are the primary benefits of digital printing over traditional methods?

Digital printing offers speed and efficiency as there is no need for a lengthy setup or plate creation. This method also allows for cost savings on small print jobs due to the lack of upfront setup costs.

How does digital printing enhance short-run print jobs?

Short-run print jobs are more economical with digital printing because it allows for printing smaller quantities without the high initial costs associated with traditional printing setups like creating plates.

Can digital printing provide a cost-effective solution for on-demand printing?

Yes, digital printing is ideal for on-demand printing as it supports the printing of exact quantities when needed, thus reducing storage space and waste associated with overproduction.

In what ways does digital printing offer greater customization options?

Digital printing enables greater customization due to its ability to easily modify images and text from one print to the next without slowing down the printing process, which is highly beneficial for personalized marketing materials.

How does the quality of digital printing compare to that of offset printing?

While offset printing is known for its high quality and color accuracy, digital printing has significantly improved and can deliver comparable quality, particularly for smaller print jobs with considerations for detail and color.

What environmental advantages does digital printing present?

Digital printing reduces waste by printing only the amount needed and eliminates the need for plates and chemicals used in traditional printing. Additionally, it often uses less energy and can even support eco-friendly inks and recyclable materials.…